|

|

|||||||||||||||||||

| Available Control Valve Models | |||||||||||||||||||||||

|

Single Seated Globe Valves |

|

||||||||||||||||||||||

|

Single seated angle Valves |

|

||||||||||||||||||||||

|

Double Seated Globe Valves |

|

||||||||||||||||||||||

|

Double Seated Angle Valves |

|

||||||||||||||||||||||

|

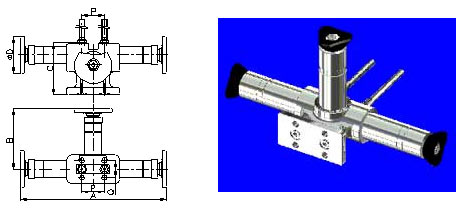

3 Way Valves |

|

||||||||||||||||||||||

|

Double Ported Valve |

VDP - Top and Bottom guided |

||||||||||||||||||||||

|

Eccentric Rotary Valve |

VFR - Flowing Type |

||||||||||||||||||||||

| Special Valves | |||||||||||||||||||||||

|

Multi Stage Valves |

|

||||||||||||||||||||||

|

Slurry & Urea Services Valve |

SDV- Self Drain |

||||||||||||||||||||||

|

Others |

|

||||||||||||||||||||||

| General Details | |||||||||

|

Type of valve |

Wafer, Flanged Short Body, Flanged Long Body, Buttweld end |

||||||||

|

Dsign Standard |

AWWA C504 upto 1800 mm, AWWA C516 2000 mm and Above, BSEN 592/ BS 5155 |

||||||||

|

Type of construction |

Cast, Fabricated |

||||||||

|

Pressure Rating |

As per AWWA - Class 25A, 25B, (For Fab.), 75A, 75B, 150A, 150B& 250B (For Cast); As per BSEN - PN2.5 to PN40 (For Cast); ANSI - 150 |

||||||||

|

Material-Body |

Cast Iron, Carbon Steel, Stainless Steel. Alloy Steel |

||||||||

|

Material Vane |

Carbon Steel, Stainless Steel, Alloy Steel |

||||||||

|

Material Seat |

Rubber-Nitrile, Btyl, Silicon, Neopreme & Viton, Teflon (Up to 500mm) |

||||||||

|

Actuators |

Manual Gear Box, Electrical & Pneumatic (Single Acting and Double Acting) |

||||||||

|

Flange Drilling |

As per AWWA C207 Class-B/D, ANSI B 16.5 Class 150, ANSI B 16.1 Class 125, BSEN 1092-1/1092-2 |

||||||||

|

Available Valve Models |

|

||||||||

|

|

|||||||||||||||||||||||||

|

Available Models |

|

|

Type |

Full bore, Full lift valve with discharge coefficient of 0.974 |

|

Size |

½ inch x 1 inch to 8 inches x 10 inches |

|

Orifice Designation |

D,E, F, G, H, J, K, L, M, N, P, Q, R, T |

|

End Connection |

Screwed or Flanged |

|

Design Code |

ASME Section-I, VIII and API 526 |

|

Set Pressure Range |

0.7 kg/sq.cm to 422 kg/sq.cm 0.7 kg/sq.cm to 40 kg/sq.cm for Full bore Safety Valves |

|

Material - Body |

Carbon Steel, Alloy Steel, Stainless Steel, Special Materials |

|

Material - Trim |

SS-316,SS-316 Stellited, 17-4 PH, special materials |

|

Seat Design |

Metal/Soft Seat |

|

Other Features |

Balancing Bellows, Plain or Packed Lever, open or closed bonnet etc. |

|

Special Certification |

IBR/ISPESL (Italian Statutory Authority) |

| Models | Size | Set Pr. |

|

2500 Series (Flanged end) |

1"X2" to 8"X10" |

.5 ~ 422 Kg/sq.cm |

|

2500 F Series (femaleXfemale srewed end) |

3/4"X1" to 2"X2" |

.5 ~ 351 Kg/sq.cm |

|

2600 Series (maleXfemale srewed end) |

1/2"X1" to 1" |

.5 ~ 140 Kg/sq.cm |

|

3500 Series (full bore SRV flanged end) |

1"X2" to b"X10" |

.5 ~ 40 Kg/sq.cm |

|

|

|||||||||||||||||||||

Manifolds for separately mounting also can be supplied as per customer requirement. Superior material of construction provides corrosion resistance and withstands high pressure & temperature applications. Back seat prevents stem blow out and provides secondary stem seal.

Directly Mounted Type: |

|

Separately Mounted Type: |

|

Directly Mounted Type: |

|

Separately Mounted Type: |

|

Note: Instrumentation Limited, Palakkad has a right to alter the contents of this document with or without notice. |

|

Type |

Flow Nozzle |

||||||||||

|

Size |

2" ~ 32" |

||||||||||

|

Pipe Material |

|

||||||||||

|

Nozzle Material |

|

||||||||||

|

Beta Ratio |

0.20 ~ 0.80 |

||||||||||

|

Coeff. Of Discharge (Cd) |

0.93 ~ 0.99 |

||||||||||

|

Standard Followed |

ISO 5167-3, ASME PTC 19.5 & BS 1042 |

|

Type |

Orifice Plate |

||||||||

|

Size Range |

1" ~ 32" |

||||||||

|

Pressure Rating |

ANSI 150,300,600,900 & 1500. |

||||||||

|

End Connection |

Flanged End (RF,RJ & Slip On) And Butt Weld |

||||||||

|

Tappings |

Flange Tapping, Corner Tapping & Radius Tapping |

||||||||

|

Flange Material |

|

||||||||

|

Orifice Plate Material |

|

||||||||

|

Beta Ratio |

0.10 ~ 0.75 |

||||||||

|

Coeff. Of Discharge (Cd) |

0.58 ~ 0.63 |

||||||||

|

Standard Followed |

ANSI B 16.36, ISO 5167-2, ASME PTC 19.5 & BS 1042 |

|

Type |

Venturi Tube |

||||||||||||||

|

Size Range |

36" ~ 48" |

||||||||||||||

|

End Connection |

Flanged End And Butt Weld |

||||||||||||||

|

Material |

|

||||||||||||||

|

Beta Ratio |

0.30 ~ 0.75 |

||||||||||||||

|

Coeff. Of Discharge (Cd) |

0.984 ~ 0.995 |

||||||||||||||

|

Standard Followed |

ISO 5167-4, ASME PTC 19.5 & BS 1042. |